Bearings are unsung heroes of the bicycle world, expected to endure extreme pressures and stresses without failures or complaints, and to do this with minimal lubrication or maintenance. The bearings used in the hubs of modern bikes must complement the performance of other hub components for optimum efficiency and durability.

What’s so special about bike hub bearings?

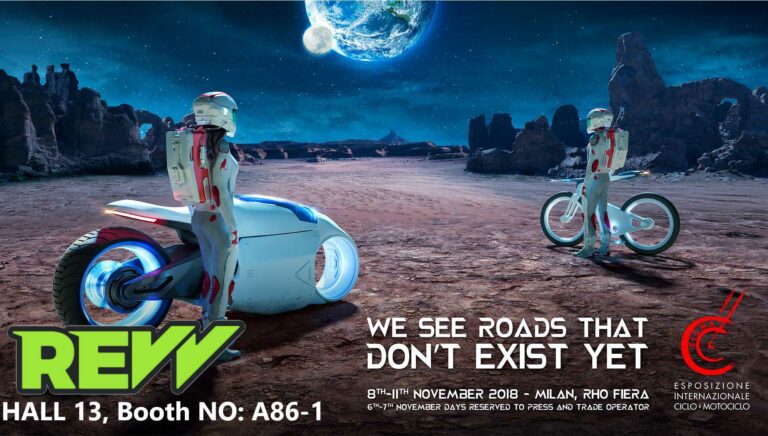

When you look at a bike hub, like the Revv RX series road bike front hub shown above, you can see the precision machined alloy casing, but not the internal mechanism. Inside the case are a set of carefully matched bearings that are crucial to the smooth, reliable operation of the hub.

Bike hub bearings are one part of a system of balanced components and design principles that make up a modern bicycle, and it’s important to consider them in relation to the other desirable and undesirable features of bike hub design and performance.

There is a lot of talk about bearings that focuses on technical comparisons of materials and frictional losses, but when we look at any bicycle setup as a complete system we might be surprised to find that the true value of well designed bearings is more about reliability than friction or weight considerations.

How much do bike hub bearings contribute to loss of performance due to friction?

Friction is the biggest enemy of the cyclist (although some people are not fond of hills either!). Friction robs your ride of power, acceleration and speed when you start pedaling and when you are freewheeling. This is why bike design, tuning, and maintenance focuses on reducing friction to improve performance.

Competitive cyclists are very aware of the importance of tire pressures and profiles in reducing friction and rolling resistance. Wheel hub bearings have a minor role to play compared to tires. Poorly maintained bike hub bearings can make a difference to the quality of your ride, but the contribution even the most basic bearing makes to the frictional resistance of a bike is minimal.

Do bike hub bearings add significant weight to your bike?

Riders and designers also pay a lot of attention to weight reduction in bicycle engineering. It’s logical that the lighter your bike is, the less effort it takes to ride it, but that’s not the whole picture. A bike can be very lightweight but be difficult to ride due to poor setup or ergonomics.

The function of a hub bearing is to keep the hub stable and the wheel spinning freely while withstanding the pressure of the weight of the rider, bicycle frame and road or trail surface impacts transmitted through the wheels and suspension. All this stress is focused on very small surface areas within the bearing. This is why durability and strength need to be priorities in bearing design.

The true value of well designed bearings is more about reliability than friction or weight considerations. When you compare the catastrophic effects of bearing failure in ruining your ride to the potential minute efficiency gains from using ceramic bearings or ultralight carbon shells it makes more sense to focus on well engineered reliability and optimized performance.

Can we have a high quality bike bearing without compromising on performance?

The answer is yes, we can do that. Revv manufactures bicycle hubs from forged CNC machined aluminum alloy. We employ exhaustive quality management procedures, like the CMM (Coordinate Measuring Machine) check on a Revv SRS SRAM XDR freehub pictured above, to ensure all our hubs are free from defects.

We apply the same quality and excellence standards to the bike hub bearings we use in our hubs as we do to the hubs themselves. This ensures long life and excellent lightweight performance while keeping costs at a level that makes Revv SRS hubs an attractive and affordable option for the majority of bike enthusiasts.

What are the benefits of using steel bearings in an alloy bike hub?

- Durable with minimal maintenance

- Smooth, dependable operation

- Excellent weight to strength ratio

For the most rugged applications we also fit steel bearings into freehubs, for eBikes and robust MTB designs. As an expert manufacturer of performance bike hubs, we apply the optimum blend of materials and technologies to suit the needs of each of our customers.

Our patented SRS (Spring Ratchet System) freehub design is sufficiently flexible to meet a wide range of specifications, and over 8,000km of road testing without failure demonstrates that our selection of bearings is the right one!