During the part processing phase, the inspection of the first piece is a pivotal step – first article inspection (FAI). This means that once the first part is completed, it undergoes a check to ensure it matches specifications. This helps maintain consistency throughout the entire production batch.

Moreover, full dimension inspections and key dimension patrols further guarantee the precision and quality of the processing.

During the assembly process, the first piece needs to be inspected to ensure that the first assembled product meets the criteria, serving as a reference for subsequent production.

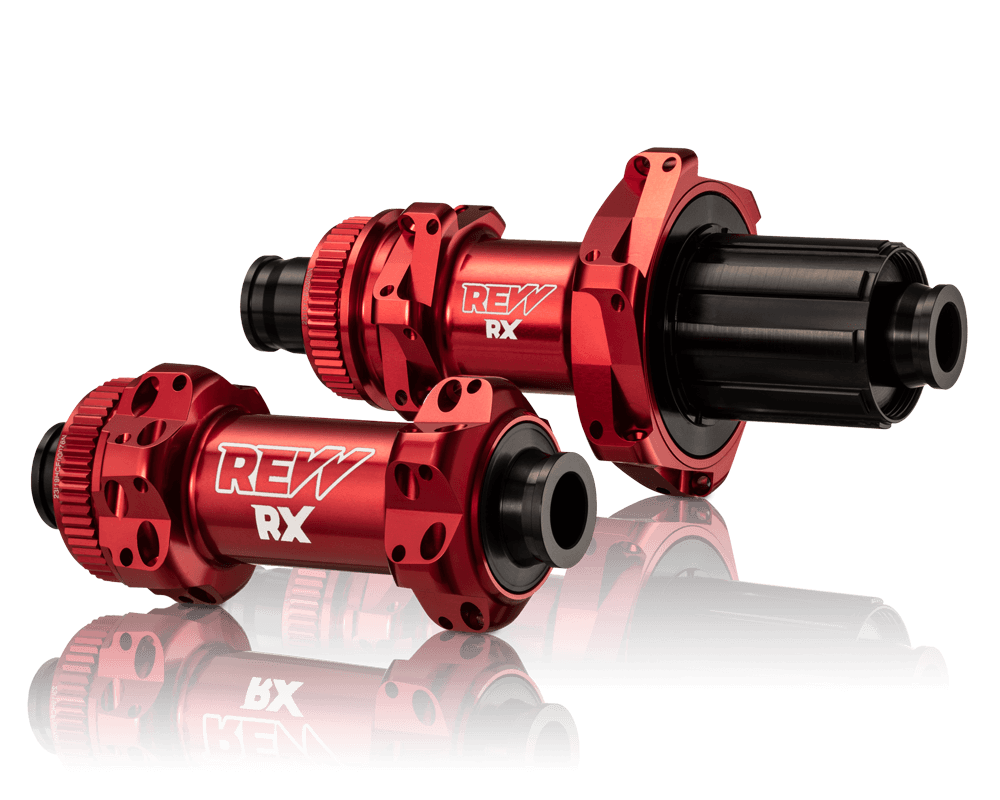

While assembling the hub, there’s a need for a 100% inspection of spindle smoothness and ratchet oil inspection according to torque specifications, ensuring product smoothness and meeting torque requirements.

Another focus is on the concentricity and dimension control of the bearing hole, ensuring product precision and consistency.

After the product is manufactured, a final quality control inspection is required. This guarantees that the finished product fulfills customer requirements and quality standards.

These rigorous inspection processes ensure the high quality of the product and, through continuous monitoring and improvement, uphold the efficiency and reliability of the production process. This helps ensure that the REVV company delivers outstanding products that meet customer expectations.

Adding to Inquiry - Production

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |