Bike hubs do a lot of work to keep your ride smooth and trouble-free. A bike hub should give you rapid hub engagement when you start to pedal, efficient power transfer from the pedals to the wheels, and smooth freewheeling. So how does the bike hub mechanism do this?

Bike hubs have come a long way since historic bicycles like the late 19th Century French Velocipede or Victorian Penny-farthing shown in the picture above. You can see that this primitive bicycle has the pedals directly connected to the front axle. The awkward design with a huge front wheel enables the cyclist to go faster without any form of gearing, but makes the bicycle top heavy, dangerous and uncomfortable to ride.

A front freewheel hub was patented in 1869, but it wasn’t until 1885 that a ‘safety’ bicycle’ was designed that featured a chain driven rear hub for propulsion. Today’s bicycles are almost all descended from that original rear-wheel driven model with a ratchet and pawl built into the hub or gear system to enable freewheeling.

Why do we drive the rear hub and not the front hub?

The simple answer is that trying to steer with the wheel you are driving is much more difficult, and it is harder to keep balance on a bicycle if you are driving the front wheel through a turn. Some budget eBikes have a powered front hub, and this adds the problem of raising the center of gravity of the bike, making it more top-heavy.

Why do you need a freewheel hub?

A freewheel hub or freehub disengages from the drive train when it’s not under load. In simple terms, when you stop pedaling the bicycle wheel is disconnected from the pedals and you don’t have to keep your feet moving to keep up. In bicycle terminology there is a difference between freewheel hub and freehub technology, but both are designed to enable freewheeling when you stop pedaling.

In very early bicycles with pedals attached directly to the hubs, like the Penny-farthing, you had to keep pedaling even when the bike was coasting or going down hill. Today you have the same problem with simple single speed bicycles with a direct drive and no gears. These are a niche market today, as they limit what you can safely do with your bicycle.

Freewheeling enables you to rest while coasting on your bicycle or going down hill, or when the motor is doing the work for you on an eBike. Without some way to disengage the pedals from the wheels when you stop pedaling you would have to keep spinning those pedals to keep up. This is why a freewheel hub is an essential part of modern bicycle design.

How does the freewheel hub work?

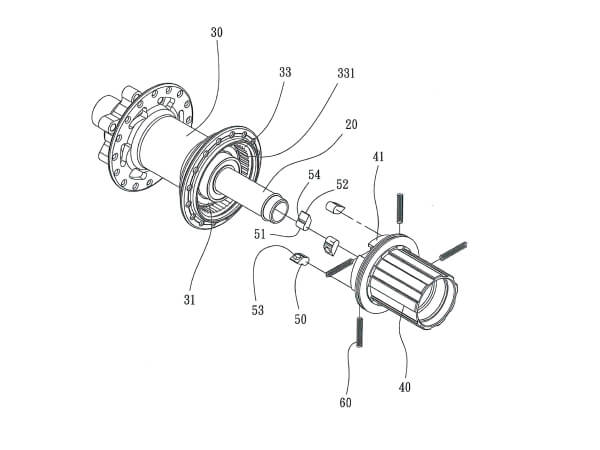

A modern freewheel hub or ‘freehub’ has a ratchet and pawl mechanism inside the hub which disengages from the axle when you stop pedaling, allowing the wheel to continue to turn without turning the pedals. When you start pedaling again the mechanism latches back into place. This is different from the older cassette based freewheel, which had the freewheeling ratchet and pawl system built into the gear cassette.

The speed and smoothness of hub engagement when pedaling depends on the design. Another significant consideration is durability, this needs to be balanced with performance. You could have a hub with a very large number of pawls, thinking this might make operation smoother and faster, but each pawl would then be smaller and more fragile.

What are the benefits of high tooth to pawl density in a freehub?

- Rapid engagement

- Better power transfer

- Faster acceleration

In practice, for high performance road bikes a six pawl design is optimum, and a four pawl design is better for absorbing the high torque and shock demands of eBikes, MTB and Gravel bikes without significantly compromising on smooth engagement. The Revv patented SRS hub design features this configuration, with six pawls as standard for road bikes and four pawls for other models.

Why is the Revv SRS the best bike hub design today?

Revv is an innovative company, and we have a history of responding to the changing needs of cyclists as lifestyles and technologies evolve. This is why we designed the patented Revv SRS (Spring Ratchet System) to meet both standard and eBike requirements for excellent, smooth power transfer. Field testing of our designs has demonstrated the proof of our concept over 8,000 km of operation without failure!

What’s special about the Revv SRS freehub?

- 3D aluminum forging of hub shells for outstanding reliability

- CNC machining of components for very tight tolerances

- Patented spring ratchet system for smooth operation under high pressure

- Balanced coil springs enable synchronous, fast, pawl engagement

- Reinforced ratchet rings for added reliability and security

- Color matched to your design requirements

The Revv SRS hub features 6 pawls and alloy shells for road bikes or 4 reinforced pawls for MTB, Gravel and eBikes. The 3D aluminum forging of our hub shells achieves higher density than conventional alloy hubs for increased torque and wear resistance. Our eBike hub is ideal for high performance mid-drive eBikes, and with a steel freehub option can absorb the additional loadings without fuss.