Electric hybrid bike hubs have to take a lot of punishment. When you add the weight of electric systems to create an eBike this increases the mechanical stresses on the bike frame and components in acceleration and braking, and from riding, track and road impacts. These stresses are transmitted through the wheel hubs, so what are the best choices for electric hybrid bike hubs that can take this punishment?

What are the challenges for manufacturing electric hybrid bike hubs?

The moment you add an electric motor to a bike, and create an eBike or eMTB, you are changing the physics and dynamics of the bike riding experience. Hybrid bikes without electric motors have long been one of the most popular bike styles for modern riders. This is why demand for electric hybrid bikes, or “hybrid eBikes” is also increasing.

Some electric hybrid bikes have front fork suspension, which softens the effect of impacts on the front hubs, but rear hubs have to be able to support the weight of the rider and the additional stresses caused by drops, impacts, and rough road or track surfaces.

Why are standard bike components not the best choice for eBike manufacturing?

To meet the demands of electric hybrid bikes, manufacturers produce many eBikes based on standard hybrid frames, hubs, wheels and accessories. Unfortunately, customers are often not satisfied with the performance, and especially the durability, of these hybrid eBikes.

To understand why, we need to take a closer look at the dynamics of how a hybrid eBike compares to a non-electric bike. There is a huge difference in the stresses and forces on a bike when it’s moving at speed compared to when it’s stationary, and we need to look at these in more detail to understand why eBike bike hubs need to be different.

What’s the most important difference between eBikes and non-eBikes?

The most obvious difference between any eBike and a non-electric bike is the added weight of motor and battery. Adding a motor also increases average bike speed. Manufacturers need to consider the impact of increased weight and speed across all eBike components to produce an eBike that customers will enjoy riding and review positively.

How does hybrid eBike weight make a difference to hub design?

eBikes will always be heavier than an equivalent non-electric bike, and hybrid eBikes are no exception. The dynamics of riding a bike, the energy required to get it moving and to stop it, and the force required to steer and maintain stability are all strongly influenced by changes in weight.

This is because the energy built up in moving objects (kinetic energy) as they increase speed isbased on a square law. When the speed of a bike doubles, its energy quadruples. This is why walking into a wall is much less painful than running into one! Cyclists ride faster on eBikes because they have a motor to assist them. This means heavier bikes that are moving faster, with more energy to absorb when riding over rough roads and trails or hitting kerbs or tree roots.

Can you use standard road bike hubs on eBikes?

Many bike manufacturers put standard road bike hubs into electric hybrids, but then suffer the consequences when riders report breakages and poor performance. A bad hub choice can ruin your ride, and in people’s minds that bad experience is associated with the entire brand, not just a faulty hub.

Revv manufactures a range of heavy duty bike hubs with contemporary cassette and brake rotor mounting options, which means that among our portfolio of high quality bike hub designs there will be a perfect match for any combination of components and engineering requirements for hybrid eBike manufacturing.

Can Revv downhill bike hubs be used for hybrid eBikes?

The heavy duty construction and Revv patented SRS ratchet system of our downhill bike hubs make them a sensible, rugged solution for hybrid eBikes. This is because the challenges of high impact downhill biking put similar stresses on bike components to the higher speeds and weights of hybrid eBikes.

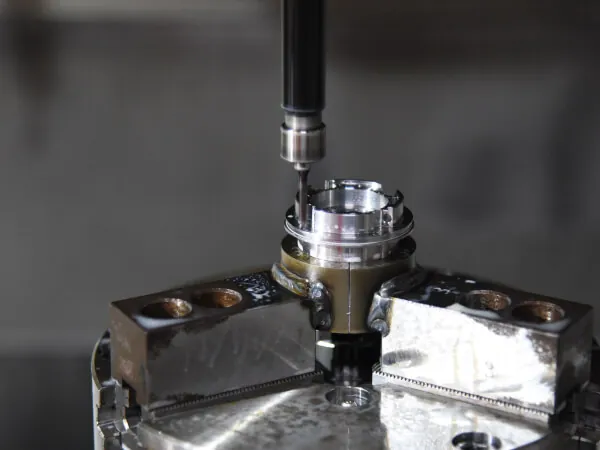

Continuous quality control for bike hub manufacturing

From checking incoming materials to final engineering compliance verification of finished bike hubs, Revv continuous quality control ensures perfect results. All SRS ratchets are inspected for torque and spring characteristics, and shells have complete geometric dimension and concentricity tests before and after assembly.

- Ratchet torque verification

- Reference checks during assembly

- Full & key dimension measurement & inspection

- Pre-shipment quality inspection

Revv bike hubs are engineered, manufactured, and verified to be a 100% match to our stringent design and performance specifications. We apply the highest quality standards to guarantee compliance with our customer requirements.

Revv MTB and eMTB hubs for hybrid eBikes

Another good option for hybrid eBikes are Revv MTB and eMTB hubs. These include choices between CNC machined forged aluminum or steel shell construction as well as all types of contemporary cassette mounting. Our rugged gravel bike hubs should also be considered for hybrid eBike manufacturing.

Why are Revv bike hubs an excellent choice for OEM manufacturers?

Our use of heavy duty bearings in our hub designs enables Revv bike hubs to absorb the extreme shock loadings the heavier hybrid eBikes of 2024 demand. We also understand that it’s not just about strength and durability because people still want to get the best performance out of their hybrid eBikes.

- Rugged SRS ratchet system

- Forged alloy CNC machined shells

- Tough, durable bearing design

- Shimano HG, Shimano Micro Spline & SRAM XDR cassettes

Low friction freewheeling with rapid engagement and disengagement of the ratchet and pawls is a signature feature of our patented SRS (Spring Ratchet System) rear hub technology. Balanced springs and a six pawl ratchet provide instant and responsive performance that riders want to feel on any bike, combined with the durability and reliability you can expect from Revv hubs.

Our excellence in bike hub manufacturing comes from our innovation and attention to detail, extensive road testing, quality control and responsiveness to customer needs. Contact us to explore which of our cost-effective bike hub options matches the needs of your hybrid eBike customers.