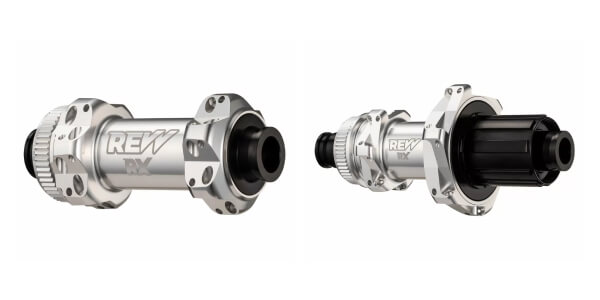

Racing bikes are light, efficient, fast, and responsive, and racing bike hubs need to be properly designed to keep up with the fast pace of road-racing bike enthusiasts. The Revv RX series of bike hubs is designed and manufactured with the needs of racing bike manufacturers in mind, offering an unmatched combination of weight reduction, low friction bearings, high efficiency and responsive freewheeling without sacrificing strength and durability.

What features do bike riders want in racing bike hub designs?

Riders will tell you that the best racing bike hubs are light, strong, and engage rapidly. Ideally they are also durable and reliable. Fortunately build and bearing quality contribute to longevity and durability, and certain types of build are also lighter by design than others. Revv uses the strongest method of lightweight hub manufacturing, which is also the method that can offer the best performance if it is done well.

Forged CNC machined hubs for better racing bike wheelsets

Forged CNC machined hub shells are an excellent foundation for any racing bike wheelset. This is because the combination of forged construction with CNC machining gives you the best of both worlds in terms of the crystalline structure of the metal, which improves strength and fatigue resistance, and perfect concentricity and dimensional accuracy, which eliminates harmonic vibration and guarantees balance.

Precision machining after forging is the best way to optimize a bike hub for performance without compromising on reliability. At Revv we optimize our bike hubs in two ways, through the innovative, efficient, functional design of our patented SRS rear freewheel hub ratchet system, and by taking extreme care to ensure exceptional quality control in manufacturing. A great hub design can be ruined by inferior manufacturing and inadequate quality control.

Why are racing road bike hubs built to exact tolerances?

Competitive cycling puts special emphasis on weight reduction across every component and system of bike design. This makes it important for OEM manufacturers to be able to guarantee that the machining and weight tolerances of racing bike hubs are very precise, and can be reliably reproduced by the manufacturer. This is why high precision machining and rigorous quality control are supremely important in racing bike hub manufacturing.

What is the quality management system we use for bike hub manufacturing?

- verification of all stock materials to ensure they meet our specifications

- full dimension and key dimension inspections during manufacturing

- assembly checks against reference pieces

- 100% checks of ratchet torque & drum concentricity

- final quality control checks of finished hubs

How do Revv racing bike hubs meet the needs of racing bike enthusiasts?

Racing bike enthusiasts want reliable high performance, with minimal drag, weight and rolling resistance. Part of good racing bike hub design is to consider how the hub fits into the wheel system to ensure minimum drag. Aerodynamic drag from wheels contributes up to 15% of the total drag caused by wind resistance on a bicycle. Revv’s lower spoke counts with straight-pull spokes help bike manufacturers keep wind resistance low while maintaining essential wheel rigidity and stability.

- Patented six pawl, responsive rear hub SRS ratchet system

- Lower spoke counts reduce wind resistance

- Straight pull spokes for lighter, stiffer, construction

- Efficient, durable, low rolling resistance bearings

- Revv hub sizing matches modern performance bike frames

- Forged & machined strong, light weight aluminum alloy construction

- 24 spoke count

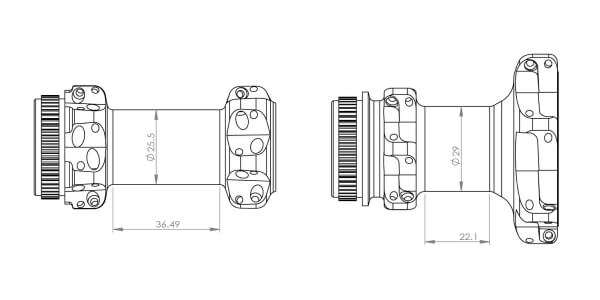

- 12 x 100mm front & 12 x 142mm rear dimensions to fit contemporary bike frames

- Tool free end caps for easy maintenance

- 8,000km of road testing without failures

We use efficient steel bearings in the front hub and in our rear SRS freewheeling hub to minimize rolling resistance without compromising on durability and longevity. Some hub manufacturers use ceramic bearings, but this reduces reliability and strength without significant weight reduction gains, and is less significant than tire design in adding to rolling resistance.

How does Revv hub technology improve cycling performance?

Our forged, CNC machined aluminum alloy construction is lighter, stronger, and more precise than casting or billet manufacturing. The precision of this method also improves concentricity and balance for improved racing bike performance by reducing harmonic vibration, making one less thing to worry about when assembling the perfect racing bike.

The immediate, smooth, response of our patented SRS (Spring Ratchet System) rear freewheeling hub is due to the balanced springs and precise modifications of the engagement system for the six pawl ratchet. Any rider can put the power on instantly and be confident of efficient freewheeling the moment they need it. This responsiveness improves the road-feel and connection that racing bikes need to deliver to today’s riders. Contact us today to find out more about our high performance solutions for racing bike hubs.