Taipei Cycle 2024, set to be a groundbreaking event, promises to showcase the latest innovations in cycling technology and sustainable transportation, attracting enthusiasts and industry professionals from around the globe.

The Taipei Cycle exhibition will be held at the Nangang exhibition center in Taipei in March 2024. The event will be heavily focused this year on product value and also sustainability as the trend towards ever greener products continues.

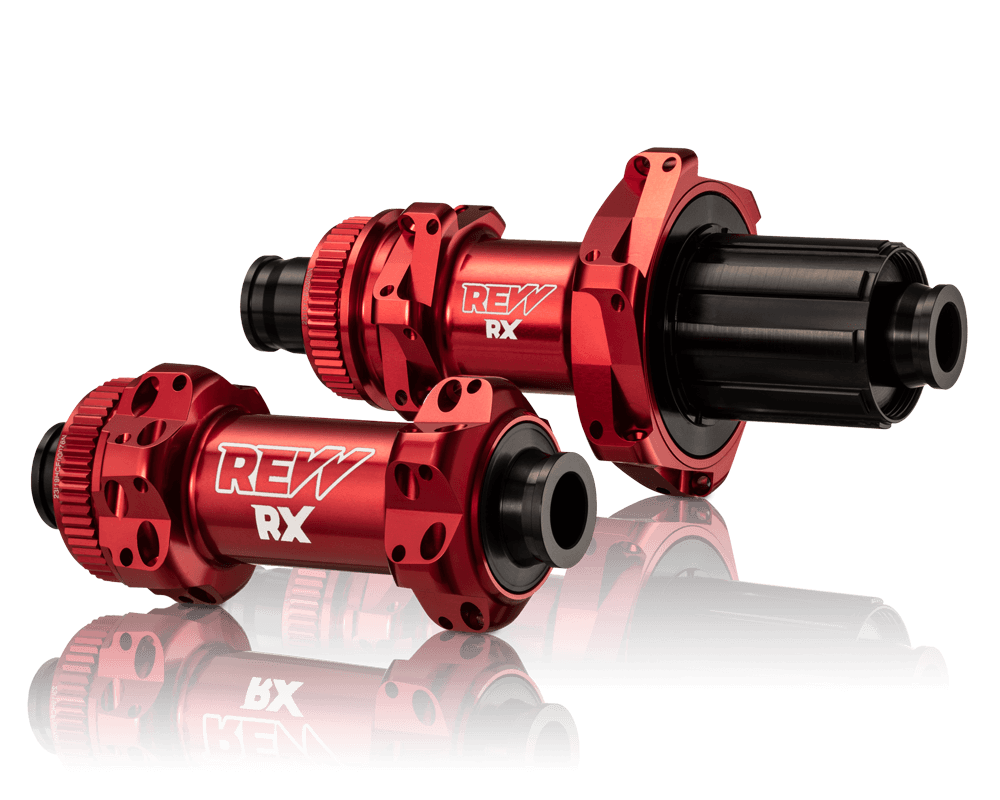

Revvcycles will be showcasing our full range of performance hubs for eMTB, MTB, Road and Gravel bikes for the first time at the Taipei Cycle show this year.

Revvcycles is excited to announce their attendance at this year’s Taipei Cycle 2024. They will be available throughout the show, ready to engage with attendees and answer any questions or inquiries about their innovative cycling products.

This presence marks an excellent opportunity for Revvcycles to connect with the cycling community and showcase their latest offerings in the industry.

BIKETECH was founded in 1988, the rise of global cycling. We have been assisting brands from the western countries to develop, produce, and sell products from Taiwan. We have extensive knowledge in bicycle parts manufacturing, with a primary focus on spoke and wheel technology.

BIKETECH keeps monitoring the quality consistency in production and supply chains to ensure high-quality and fulfill customers stringent performance requirements.

“Creating an exceptional riding experience” is our commitment. How to meet our high quality standards is what drives Biketech.

BIKETECH has developed the high-efficiency SRS, a patented ratchet system. SRS technology is the foundation of our new brand – REVV, which made its debut in 2023 EUROBIKE, aiming to give riders more enjoyable experiences.

During the part processing phase, the inspection of the first piece is a pivotal step – first article inspection (FAI). This means that once the first part is completed, it undergoes a check to ensure it matches specifications. This helps maintain consistency throughout the entire production batch.

Moreover, full dimension inspections and key dimension patrols further guarantee the precision and quality of the processing.

During the assembly process, the first piece needs to be inspected to ensure that the first assembled product meets the criteria, serving as a reference for subsequent production.

While assembling the drum, there’s a need for a 100% inspection of spindle smoothness and ratchet oil inspection according to torque specifications, ensuring product smoothness and meeting torque requirements.

Another focus is on the concentricity and dimension control of the bearing hole, ensuring product precision and consistency.

After the product is manufactured, a final quality control inspection is required. This guarantees that the finished product fulfills customer requirements and quality standards.

These rigorous inspection processes ensure the high quality of the product and, through continuous monitoring and improvement, uphold the efficiency and reliability of the production process. This helps ensure that the REVV company delivers outstanding products that meet customer expectations.

Adding to Inquiry - Taipei Cycle Exhibition Nangang 2024

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |